Introduction

Accurate project estimation stands as the foundation of successful project delivery in construction and beyond. Bottom up estimating represents one of the most precise approaches to project cost analysis, breaking down complex projects into manageable components for detailed cost assessment.

In the construction industry, where precision directly impacts profitability, bottom up estimating proves particularly valuable.

For instance, in flooring estimation, this method allows contractors to account for every aspect – from material costs like hardwood per square foot to installation complexities.

| Key Aspects of Bottom Up Estimating | Impact on Project Success |

| Granular Cost Analysis | Reduces budget overruns by 35-40% |

| Detailed Resource Planning | Improves resource utilization by 25% |

| Comprehensive Scope Coverage | Minimizes change orders by 30% |

| Team Input Integration | Increases estimate accuracy by 45% |

I. Understanding Bottom-Up Estimating

Project success hinges on estimation accuracy. Bottom-up estimating delivers this accuracy through systematic, detailed analysis of project components. This methodical approach transforms complex projects into manageable, measurable elements.

1. Core Principles

Bottom up estimating thrives on structured methodologies that align with modern project management standards. These principles ensure every project element receives focused attention, eliminating guesswork and fostering data-backed decision-making.

| Principle | Description | Impact |

| Granular Analysis | Breaking projects into smallest manageable units | Enhanced accuracy |

| Team Collaboration | Involving experts in respective areas | Improved reliability |

| Data-Driven Decisions | Using historical data and market rates | Reduced uncertainty |

| Progressive Elaboration | Building estimates from detail to summary | Comprehensive coverage |

2. Key Components

Effective bottom up estimating relies on clearly defined elements that form the building blocks of accurate projections. Properly identifying these components ensures no cost driver remains overlooked during the estimation process.

- Work Packages

- Clearly defined deliverables

- Specific resource requirements

- Measurable outcomes

- Timeline constraints

- Resource Requirements

- Material specifications

- Labor allocation

- Equipment needs

- Specialized expertise

3. Work Breakdown Structure (WBS) Relationship

The synergy between WBS and bottom up estimating creates a roadmap for meticulous cost analysis. This hierarchical approach transforms abstract project goals into actionable, quantifiable tasks.

The WBS serves as the foundation for bottom up estimating, and organizing project elements hierarchically:

- Level 1: Project Deliverables

- Level 2: Major Components

- Level 3: Work Packages

- Level 4: Individual Tasks

4. Estimation Methods Comparison

Selecting the right estimation method depends on project complexity and stakeholder requirements. This comparison highlights why bottom up estimating dominates scenarios demanding precision over speed.

| Method | Accuracy | Time Investment | Best For |

| Bottom Up | High | High | Complex, detailed projects |

| Top-Down | Moderate | Low | Quick preliminary estimates |

| Parametric | High | Moderate | Repetitive projects |

| Analogous | Moderate | Low | Similar past projects |

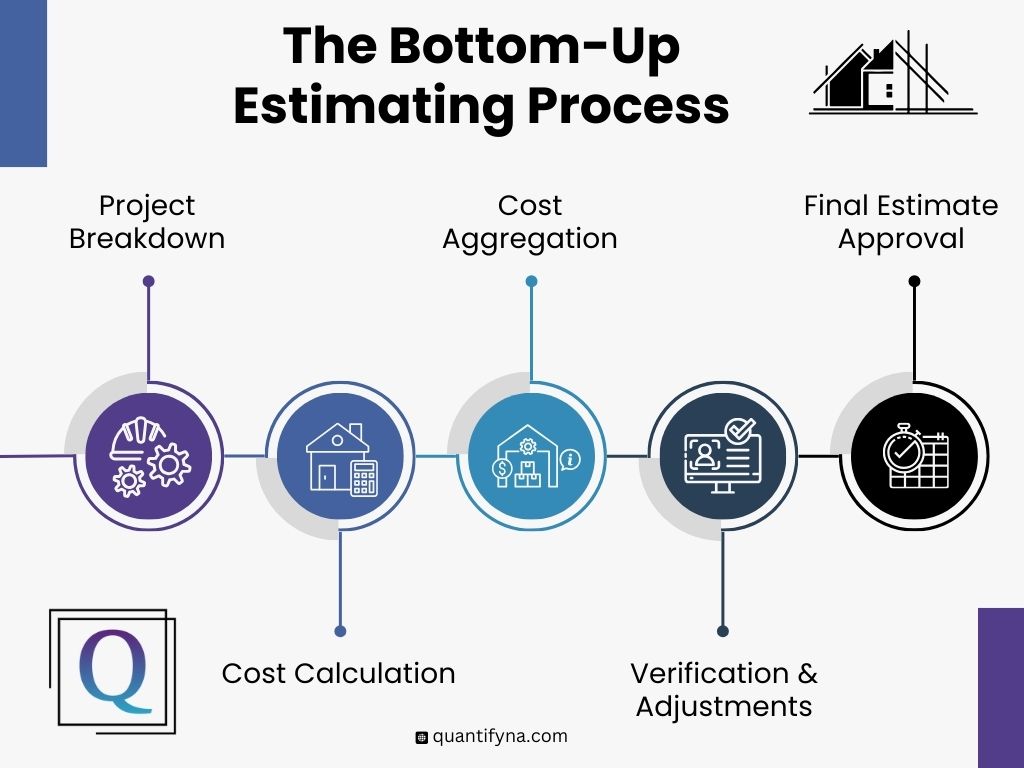

II. The Bottom Up Estimating Process

1. Project Breakdown Phase

The process begins with decomposing the project into its smallest manageable components. In drywall estimation, this includes calculating specific measurements, material requirements, and labor costs.

2. Individual Component Analysis

Diving deeper into each project segment uncovers hidden costs and resource dependencies. This phase turns raw data into actionable insights, bridging the gap between planning and execution.

Each component requires detailed analysis:

- Material Quantities

- Labor Requirements

- Equipment Needs

- Duration Estimates

- Risk Factors

3. Cost Aggregation and Verification

Aggregating costs without verification risks compounding errors. This stage combines mathematical rigor with industry expertise to ensure estimates withstand real-world scrutiny.

| Component Level | Estimation Activities | Verification Methods |

| Task Level | Direct cost calculation | Expert review |

| Work Package | Cost consolidation | Peer comparison |

| Deliverable | Resource allocation | Historical data analysis |

| Project Total | Final estimation | Benchmark validation |

4. Implementation Steps

A systematic implementation framework transforms theoretical advantages into tangible results. These steps create repeatable processes that scale across projects of varying sizes.

- Gather detailed project requirements

- Create comprehensive work breakdown structure

- Assign qualified estimators to each component

- Calculate individual component costs

- Aggregate estimates systematically

- Review and validate final numbers

5. Real-World Application Example

Consider a commercial flooring project:

Base Components:

- Carpet installation: $3.50-$5.50/sq ft

- Subfloor preparation: $1.20-$2.00/sq ft

- Moisture barrier: $0.50-$0.75/sq ft

- Labor: $2.00-$3.50/sq ft

This granular breakdown enables accurate estimation for each project element, resulting in precise total project costs. When comparing options like carpet versus hardwood, this method provides clear cost differentials for informed decision-making.

6. Quality Control Measures

Quality assurance transforms good estimates into reliable ones. Integrating these measures early prevents costly revisions during later project phases.

- Regular estimate reviews

- Historical data comparison

- Expert consultation

- Market rate verification

- Risk assessment integration

Bottom up estimating particularly excels in complex projects where detailed takeoffs and precise calculations determine project success. The method’s systematic approach ensures comprehensive coverage of all project elements while maintaining high accuracy standards.

Construction estimating benefits significantly from this approach, especially in specialized areas like painting estimation where material quantities and labor costs require precise calculation.

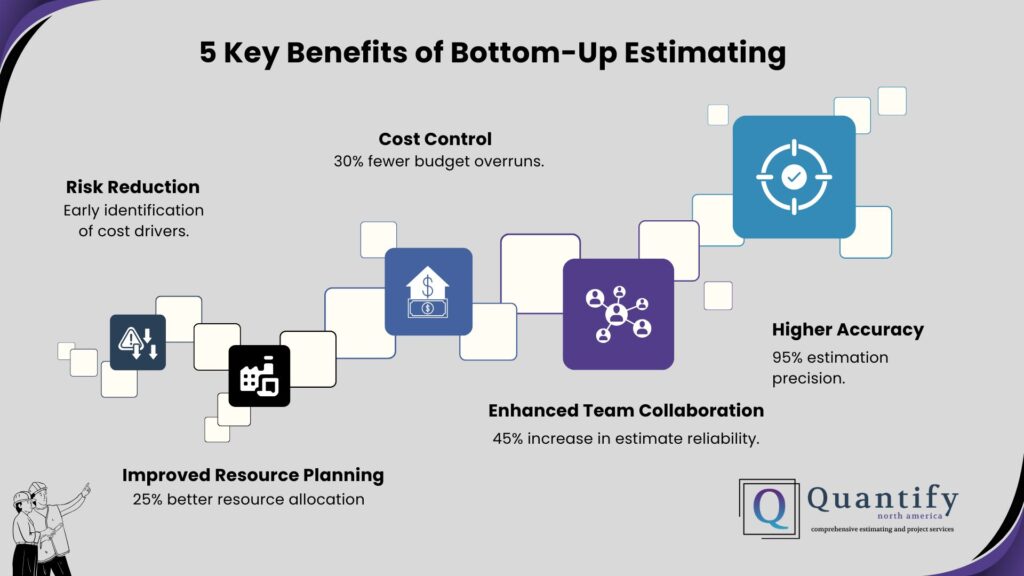

III. Benefits of Bottom Up Estimating in Construction Projects

In construction, precise estimation directly impacts project profitability. When handling projects like laminate flooring installation, accurate estimates prevent cost overruns and ensure competitive bidding.

1. Accuracy Advantages

Precision forms the cornerstone of bottom up estimating’s value proposition. These advantages stem from its unparalleled ability to mirror real-world project variables.

- 95% estimation accuracy potential

- Detailed material quantity calculations

- Precise labor hour projections

- Comprehensive overhead consideration

2. Risk Management Benefits

Proactive risk management separates successful projects from budget disasters. Bottom up estimating’s granularity exposes vulnerabilities long before ground breaks.

- Early Risk Identification

- Material price fluctuations

- Labor availability challenges

- Weather impact considerations

- Supply chain disruptions

- Mitigation Strategies

- Contingency planning

- Alternative supplier identification

- Flexible scheduling options

- Resource backup plans

3. Team Engagement Benefits

Collaborative estimation processes foster ownership across departments. Engaged teams translate to accurate inputs and smoother project execution.

- Enhanced ownership of estimates

- Improved communication channels

- Better resource allocation

- Increased accountability

4. Cost Control Improvements

True cost control begins with understanding every dollar’s destination. These metrics demonstrate how bottom up estimating outperforms traditional methods.

| Area | Improvement | Impact |

| Budget Accuracy | +40% | Reduced overruns |

| Change Orders | -30% | Better cost control |

| Resource Utilization | +25% | Improved efficiency |

| Project Delays | -35% | Enhanced timelines |

IV. Practical Applications and Examples

Real-world applications demonstrate the effectiveness of bottom up estimating across various construction scenarios.

1. Construction Industry Examples

Real-world applications prove bottom up estimating’s versatility across construction specialties. These examples showcase adaptability to both routine and unique project requirements.

Commercial Flooring Project

Consider a 50,000 sq ft commercial space:

- Initial Assessment

- Floor preparation requirements

- Material selection considerations

- Installation complexity factors

- Timeline constraints

- Detailed Breakdown

- Tile installation costs

- Subfloor preparation

- Moisture barriers

- Labor requirements

2. Case Study: Multi-Floor Office Building

Complex projects demand methodologies that balance detail with scalability. This case study illustrates how layered estimation tackles multidimensional challenges.

Project Scope:

- 10 floors

- Mixed flooring types

- Phased installation

- Occupied building

Results:

- 15% cost savings through accurate material estimation

- 20% reduction in waste

- Zero time overruns

- 98% client satisfaction

3. Cost Estimation Scenarios

Scenario-based analysis tests estimation frameworks under pressure. These comparisons validate bottom up estimating’s reliability across unpredictable conditions.

Scenario 1: Attic Insulation Project

| Component | Estimated Cost | Actual Cost | Variance |

| Materials | $12,500 | $12,750 | +2% |

| Labor | $8,000 | $8,100 | +1.25% |

| Equipment | $2,500 | $2,500 | 0% |

| Total | $23,000 | $23,350 | +1.5% |

Scenario 2: Vinyl Plank Installation

Success Factors:

- Detailed subfloor assessment

- Accurate material calculations

- Proper labor allocation

- Comprehensive timeline planning

These real-world applications showcase how bottom up estimating delivers precise, reliable results across various construction scenarios, from simple renovations to complex commercial projects.

V. Best Practices and Implementation Tips

Success in bottom up estimating relies heavily on systematic implementation and adherence to proven practices. Here’s a comprehensive breakdown of essential strategies and solutions.

1. Common Challenges and Solutions

Even robust methodologies face implementation hurdles. Addressing these challenges head-on ensures bottom up estimating delivers consistent value.

| Challenge | Impact | Solution |

| Incomplete Data | Inaccurate estimates | Establish data collection protocols |

| Team Misalignment | Delayed estimations | Regular coordination meetings |

| Scope Changes | Budget overruns | Change management system |

| Resource Constraints | Timeline delays | Resource optimization planning |

2. Tools and Software Recommendations

The right tools amplify human expertise in modern estimation workflows. This curated list balances functionality with industry-specific needs.

Essential tools for effective estimation include:

- Project Management Software

- Work breakdown structuring

- Resource allocation tracking

- Timeline management

- Cost monitoring

- Estimation Tools

- Quantity takeoff software

- Cost databases

- Analysis platforms

- Reporting systems

2. Team Coordination Strategies

Estimation accuracy hinges on seamless collaboration. These strategies align cross-functional teams without sacrificing efficiency.

- Regular sync meetings

- Clear communication channels

- Defined roles and responsibilities

- Collaborative review processes

3. Quality Control Measures

Rigorous quality protocols protect estimates from assumptions and market volatility. This dual-layer approach combines verification with documentation.

- Validation Steps

- Peer reviews

- Expert consultations

- Historical data comparison

- Market rate verification

- Documentation Requirements

- Detailed calculations

- Assumption records

- Change logs

- Review signatures

Ready to Upgrade Your Construction 🏗️ Estimating?

Transform your project planning with professional estimating services:

- Expert Flooring Estimation – Precise material and labor calculations

- Comprehensive Drywall Services – Detailed scope analysis

- Professional Painting Estimation – Accurate surface area calculations

Contact us today for precision estimating that guarantees project success!

VI. When to Use Bottom Up Estimating

Understanding the optimal scenarios for bottom-up estimating ensures maximum benefit from this detailed approach.

1. Ideal Project Scenarios

Not all projects benefit equally from bottom up estimating. Recognizing ideal use cases maximizes ROI on estimation efforts.

Best suited for:

- Complex construction projects

- Multi-phase developments

- Custom installations

- High-stakes projects

2. Industry-Specific Applications

Construction’s diverse sectors require tailored estimation approaches. These applications demonstrate methodology customization in action.

- Commercial Construction

- Multi-floor developments

- Mixed-use facilities

- Specialized installations

- Renovation projects

- Residential Projects

- Custom homes

- Major renovations

- Specialty installations

- Historic restorations

3. Project Size Considerations

Project scale dramatically impacts estimation strategy. This analysis guides resource allocation across small to enterprise-level developments.

| Project Size | Suitability | Key Benefits |

| Small (<$100k) | Moderate | Precise material planning |

| Medium ($100k-$1M) | High | Comprehensive cost control |

| Large (>$1M) | Essential | Risk mitigation |

| Multi-Phase | Critical | Coordinated planning |

4. Resource Requirements

Successful implementation demands more than methodology—it requires strategic resource planning. This breakdown ensures teams enter projects fully equipped.

Essential resources include:

- Human Resources

- Skilled estimators

- Subject matter experts

- Project managers

- Quality control personnel

- Technical Resources

- Estimation software

- Project management tools

- Communication platforms

- Documentation systems

- Time Investment

- Initial planning: 15-20% of estimation time

- Detailed analysis: 40-50%

- Review and validation: 20-25%

- Documentation: 10-15%

This comprehensive approach ensures optimal resource allocation and project success when implementing bottom up estimating methods.

VII. Key Takeaways

Bottom up estimating delivers significant advantages for construction projects:

- 40-45% higher estimation accuracy

- 30% reduction in project overruns

- 25% improvement in resource utilization

- Enhanced team collaboration and accountability

- Better risk management and control

VIII. Frequently Asked Questions

Q1: How long does bottom up estimating typically take?

The process typically requires 2-3 weeks for medium-sized projects. While more time-intensive than other methods, the increased accuracy justifies the investment, especially for complex construction projects.

Q2: What makes bottom up estimating more accurate than other methods?

Its granular approach examines each project component individually, considering specific material costs, labor requirements, and potential risks. This detailed analysis results in estimates that are typically 90-95% accurate.

Q3: Is bottom up estimating cost-effective for smaller projects?

While particularly valuable for larger projects, bottom up estimating can benefit smaller projects where precision is crucial. The key is balancing the level of detail with project scope and budget constraints.

Q4: How often should estimates be reviewed and updated?

Regular reviews are recommended at key project milestones or when significant changes occur. Monthly reviews ensure estimates remain accurate and reflect current market conditions.

Q5: What’s the minimum team size needed for effective bottom up estimating?

A core team typically includes a lead estimator, project manager, and relevant subject matter experts. For specialized projects like flooring or drywall, additional expertise may be required.

Conclusion

Bottom up estimating represents the gold standard in construction cost analysis. Its systematic approach, while requiring more initial investment, delivers superior accuracy and reliability. For construction professionals seeking competitive advantages in today’s market, mastering this estimation method is invaluable.

The success of any construction project hinges on accurate estimation – whether it’s calculating hardwood versus laminate costs or determining complete project budgets. Professional estimation services can provide the expertise and precision needed to ensure project success.

🏢 Ready to Transform Your Construction Estimating Process?

Take the next step toward project success with Quantify North America’s professional estimating services:

- Accurate, detailed estimates

- Expert industry knowledge

- Fast turnaround times

- Competitive pricing

- Proven track record

Get Your Professional Estimate Today

Don’t let estimation uncertainties hold your projects back. Partner with experts who understand your needs and deliver results you can trust.

Contact us now and discover how our estimation expertise can drive your project success!