Introduction:

For contractors and construction professionals, providing accurate and competitive bids is crucial. Attic insulation is a common project, impacting both residential and commercial properties’ energy efficiency.

Understanding the costs associated with attic insulation is essential for developing realistic proposals and winning bids. This comprehensive guide breaks down the factors influencing attic insulation costs, providing the information you need for precise estimates, just like the services offered by Quantify North America.

We’ll cover everything from material choices to labor, regional variations, and even potential hidden costs.

Why Attic Insulation Matters (and Why Accurate Estimating is Key)

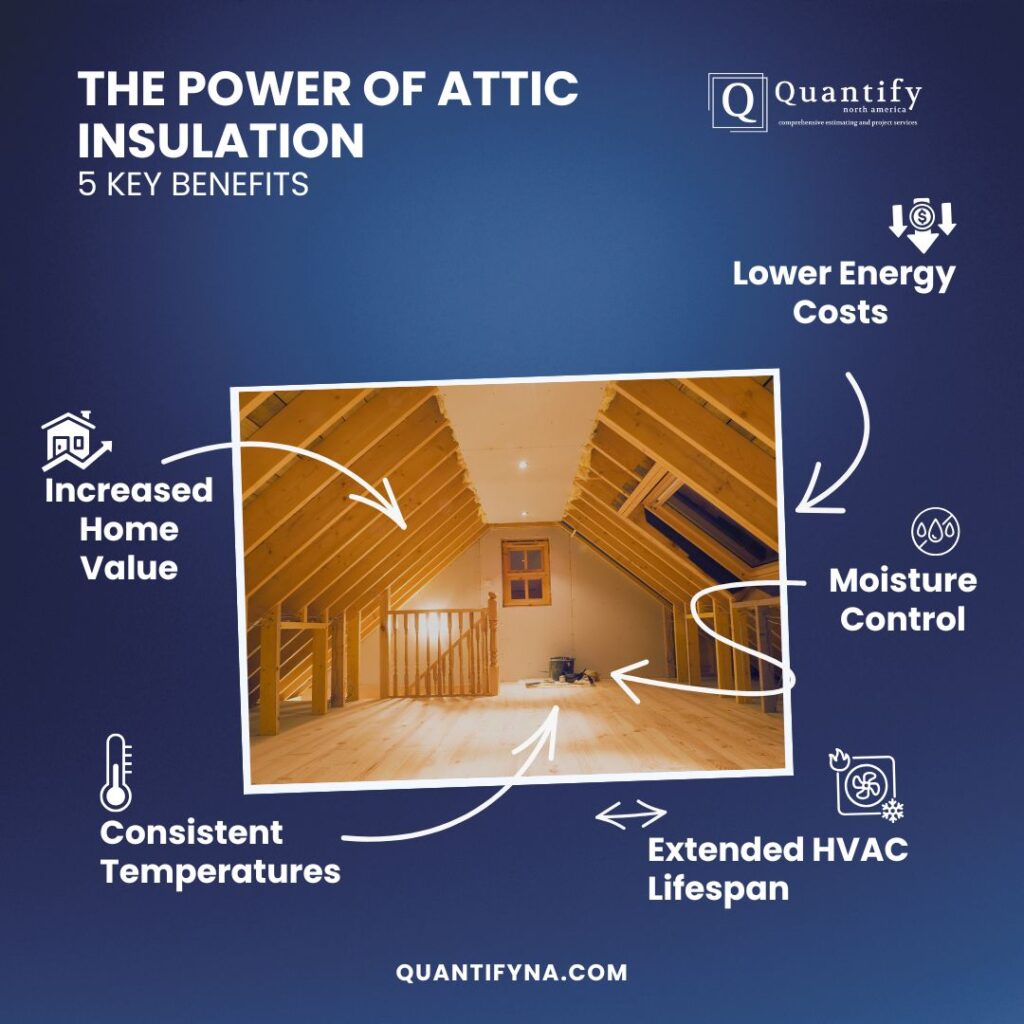

Before diving into the numbers, let’s briefly touch on why attic insulation is so important:

- Energy Efficiency: A properly insulated attic drastically reduces heat transfer. In winter, it keeps heat inside; in summer, it keeps heat out. This translates to lower energy bills for the property owner.

- HVAC Longevity: By reducing the workload on heating and cooling systems, insulation extends their lifespan.

- Comfort: A well-insulated attic helps maintain consistent temperatures throughout the building, eliminating hot and cold spots.

- Moisture Control: Proper insulation, combined with adequate ventilation, can help prevent moisture buildup and potential mold growth.

- Soundproofing: some insulation also contributes to some soundproofing to a structure

For contractors, accurate cost estimation for attic insulation is paramount. Underestimating can lead to lost profits, while overestimating can cost you the job. This guide will help you avoid both pitfalls.

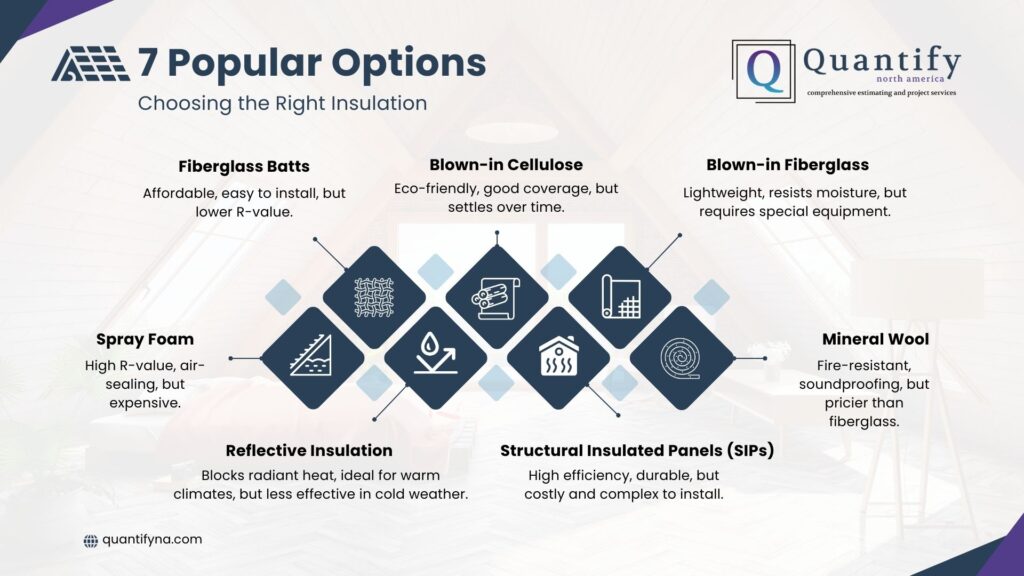

1- Types of Attic Insulation Materials: Pros, Cons, and Cost Considerations

The choice of insulation material is a primary driver of cost. Here’s a breakdown of common options:

1. Fiberglass Batt Insulation Overview

| Feature | Details |

| Description | Pre-cut sections of fiberglass fibers, often faced with paper or foil act as a vapor barrier. |

| Pros | Relatively inexpensive Widely available Easy to install, especially in unfinished attics with standard joist spacing |

| Cons | Can irritate skin and lungs during installation; protective gear is essential Lower R-value per inch compared to some other options Prone to air leaks and moisture absorption, which can lead to mold growth |

| Average Cost | $0.50 – $1.50 per square foot (material only) |

2. Blown-In Cellulose Insulation Overview

| Feature | Details |

| Description | Made from recycled paper products treated with fire retardants. Installed using a blowing machine. |

| Pros | Higher R-value than fiberglass batts Environmentally friendly Good for filling irregular spaces and existing walls |

| Cons | Requires specialized equipment (blowing machine) Can settle over time, reducing effectiveness |

| Average Cost | $0.80 – $2.00 per square foot (material only) |

3. Blown-In Fiberglass Insulation Overview

| Feature | Details |

| Description | Similar to cellulose but made from fiberglass fibers. |

| Pros | Fills cavities easily Resists moisture Minimal settling |

| Cons | Can irritate lungs and skin Proper ventilation is important |

| Average Cost | $1.00 – $2.50 per square foot (material only) |

4. Spray Foam Insulation Overview

| Feature | Details |

| Description | Polyurethane foam sprayed into place, expanding to fill cavities. Open-cell is less dense and affordable, while closed-cell is denser, has a higher R-value, and acts as a vapor barrier. |

| Pros | Highest R-value per inch (especially closed-cell) Excellent air sealing Reduces drafts Can add structural rigidity |

| Cons | Most expensive option Typically requires professional installation Off-gassing during installation (requires ventilation) |

| Average Cost | Open-Cell: $0.45 – $1.00 per board foot (one square foot at 1-inch thickness)Closed-Cell: $1.00 – $2.50 per board foot |

5. Mineral Wool Insulation Overview

| Feature | Details |

| Description | Made from rock and furnace slag. Available in both batts and blown-in applications. |

| Pros | Excellent fire resistance Repels water Dense, providing soundproofing properties |

| Cons | Higher cost |

| Average Cost | Batts: $1.50 – $2.50 per sq ftLoose Fill (Blown-In): $2.00 – $3.00 per sq ft |

6. Reflective Insulation Overview

| Feature | Details |

| Description | Made of reflective materials (like foil) to reflect radiant heat. Often used alongside other insulation types. |

| Pros | Effective in hot climates Reduces radiant heat gain |

| Cons | – Less effective in cold climates- Primarily addresses radiant heat, not conductive heat transfer |

| Average Cost | $0.20 – $1.00 per square foot (material only) |

7. Structural Insulated Panels (SIPs) Overview

| Feature | Details |

| Description | Made from an insulating foam core sandwiched between two structural boards. Commonly used in new construction. |

| Pros | – Excellent energy efficiency – Quicker build times |

| Cons | – Very high upfront cost – Modifications can be difficult |

| Average Cost | $8.00 – $15.00 per square foot |

Important Note: Material costs are estimates. Prices vary significantly based on manufacturer, quantity purchased, and local market conditions. Always obtain quotes from suppliers for accurate pricing.

2- Factors Influencing the Total Cost of Attic Insulation

Beyond material costs, several factors contribute to the overall project expense:

- Attic Size and Complexity: The larger the attic, the more insulation required, directly impacting material and labor costs. Attics with unusual shapes, multiple levels, or obstructions (like ductwork) will increase labor time.

- R-Value Requirements: The R-value represents the insulation’s resistance to heat flow. Building codes and climate zones dictate minimum R-value requirements. Higher R-values typically mean thicker insulation or a more expensive material, increasing costs. (Example: Northern climates require higher R-values than Southern climates).

- Labor Costs: Labor rates vary significantly by region and contractor. Professional installation will add to the overall cost, but it ensures proper installation and often comes with warranties. Complexity (difficult access, obstructions) will increase labor hours.

- Preparation Work:

- Old Insulation Removal: If existing insulation is damaged, contaminated, or needs to be replaced, removal will add to the cost. This can range from $1.00 – $3.00 per square foot, depending on the type of insulation and difficulty of removal. Asbestos removal requires specialized contractors and significantly higher costs.

- Air Sealing: Before installing insulation, it’s crucial to seal air leaks in the attic floor (around pipes, wires, light fixtures, etc.). This improves energy efficiency and prevents drafts. Air sealing can be a DIY task or a professional service, adding to the cost.

- Ventilation: Proper attic ventilation is essential to prevent moisture buildup and ice dams. Adding or improving ventilation (soffit vents, ridge vents, gable vents) may be necessary.

- Cleaning and Debris Removal: The attic may need to be cleaned of debris, dust, or rodent droppings before insulation can be installed.

- Accessibility: Attic location can raise costs for more diffcult access. Limited Access could result in longer project time and possibly special equipment.

- Geographic Location: As mentioned, both material and labor costs vary by location. Rural areas might have lower labor rates but potentially higher material transportation costs. Urban areas often have higher labor rates.

- Permits: Some municipalities require permits for insulation work, especially if it involves altering the structure or ventilation.

3- DIY vs. Professional Installation: A Cost-Benefit Analysis

- DIY:

- Pros: Lower labor costs, potential for significant savings, flexible scheduling.

- Cons: Requires time and effort, potential for improper installation (reducing effectiveness), risk of injury (especially with fiberglass), may void manufacturer warranties if not installed correctly, requires purchasing or renting tools.

- Best Suited For: Simple attic layouts, batt insulation, homeowners with experience in home improvement projects.

- Professional Installation:

- Pros: Ensures proper installation, experience with various insulation types, access to specialized equipment, warranties on labor and materials, faster completion time, handles permits and inspections.

- Cons: Higher overall cost due to labor charges.

- Best Suited For: Complex attic layouts, spray foam insulation, blown-in insulation (requires specialized equipment), homeowners who prefer a hands-off approach.

4- Average Cost Estimates (Including Labor)

Providing a single “average cost” is misleading due to the many variables. However, we can offer a range of estimated total costs (material + labor) based on common scenarios:

| Insulation Type | Average Total Cost (per sq ft) | Notes |

| Fiberglass Batts | $1.50 – $3.50 | Can be DIY-installed, cost varies based on R-value |

| Blown-In Cellulose | $1.80 – $4.00 | Typically requires professional installation |

| Blown-In Fiberglass | $2.00 – $4.50 | Typically requires professional installation |

| Open-Cell Spray Foam | $1.50 – $3.00 (per board foot) | Professional installation almost always required |

| Closed-Cell Spray Foam | $3.00 – $5.50 (per board foot) | Professional installation almost always required |

| Mineral Wool Batts | $2.50 – $4.50 | Professional installation recommended for optimal fit. |

| Mineral Wool (Loose Fill) | $3.00 – $5.00 | Requires Blow-In install by Professional. |

| Reflective Insulation | $0.50 – $2.00 | Often used in conjunction with other insulation types |

| Structural Insulated Panels (SIPs): | $9.00 – $16.00 | used in construction or large additions- includes labor |

Example Scenario:

A 1,500 square foot attic in a moderate climate zone, requiring R-38 insulation:

- Fiberglass Batts (DIY): $2,250 – $5,250 (material + basic tools)

- Blown-In Cellulose (Professional): $2,700 – $6,000

- Closed-Cell Spray Foam (Professional): $4,500 – $8,250 (assuming 1-inch thickness, which may not be sufficient for R-38 in all areas)

Hidden Costs and Potential Problems:

- Mold Remediation: If mold is present, it must be professionally remediated before insulation can be installed. This can add significantly to the cost.

- Pest Infestations: Rodents or insects in the attic can damage insulation and require extermination.

- Water Damage: Roof leaks must be repaired before insulation is installed. Water-damaged insulation needs to be replaced.

- Electrical Wiring Issues: Outdated or unsafe wiring may need to be addressed before insulation is installed.

- Corrective insulation: Sometimes previously completed work must be removed in order to complete the job right

5- Tips for Saving Money on Attic Insulation (Without Compromising Quality):

- Get Multiple Quotes: Obtain bids from several reputable contractors to compare pricing and services.

- Consider Air Sealing: Thorough air sealing can reduce the amount of insulation needed, saving money.

- Choose the Right Insulation for Your Climate: Don’t overspend on a higher R-value than necessary.

- DIY (if appropriate): If you have the skills and time, installing batt insulation yourself can save on labor.

- Look for Rebates and Incentives: Many utility companies and government agencies offer rebates or tax credits for energy-efficient home improvements, including insulation.

- Prioritize: If your budget is limited, focus on insulating the areas with the greatest potential for heat loss (usually the attic floor).

6- The Long-Term Return on Investment (ROI)

While attic insulation has upfront costs, it provides a significant return on investment through:

- Lower Energy Bills: Expect to see a reduction in heating and cooling costs. The exact savings depend on your climate, energy usage, and the previous insulation level.

- Increased Home Value: A well-insulated home is more attractive to buyers.

- Improved Comfort: A more comfortable living environment year-round.

- Extended HVAC System Life: Reduced wear and tear on your heating and cooling equipment.

7- Regional Cost Variations

Understanding regional differences is crucial for accurate cost estimation. Location significantly impacts both material and labor costs for attic insulation projects.

| Region | Average Cost Range* | Key Considerations |

| Northeast | $1.90 – $4.50/sq ft | Higher R-value requirements (R-49 to R-60), stricter building codes, higher labor costs in urban areas |

| Midwest | $1.70 – $4.00/sq ft | Variable seasonal conditions require comprehensive insulation, moderate labor costs |

| Southeast | $1.50 – $3.50/sq ft | Focus on moisture resistance and cooling efficiency, lower R-value requirements (R-30 to R-38) |

| Southwest | $1.60 – $3.75/sq ft | Emphasis on heat reflection and ventilation, varied material availability |

| West Coast | $1.80 – $4.25/sq ft | Diverse climate zones, higher labor costs in urban areas, strict energy codes |

*Cost ranges include materials and labor for standard attic insulation projects. Actual costs may vary based on specific location, project requirements, and market conditions.

These regional variations stem from differences in climate requirements, local building codes, labor market conditions, and material availability. Always consult local building codes and energy efficiency requirements when planning an attic insulation project.

Conclusion: Mastering Attic Insulation Costs for Project Success

Investing in attic insulation offers significant long-term returns. However, for contractors, the path to profitability hinges on accurate cost estimation.

Failing to accurately answer the question “How much does it cost to insulate an attic?” can lead to lost bids or unprofitable projects.

This guide has explored the critical factors influencing attic insulation costs: material selection, labor expenses, regional variations, and potential hidden costs.

By thoroughly understanding these elements, contractors can develop precise estimates, ensuring competitive bids and satisfied clients. Mastering the complexities of estimating “how much does it cost to insulate an attic,” sets the stage for successful project execution and strengthens a contractor’s reputation for reliability.

Ready to Ease Up Your Estimating Process?

Are you tired of the guesswork involved in estimating attic insulation costs? Partner with Quantify North America and transform your approach.

Our innovative platform streamlines the estimating process, delivering accurate material lists, reliable quantity takeoffs, and the confidence to win more bids.

Contact us today to discover how we can help you build a more profitable and sustainable business. Let us help you definitively answer the question, “How much does it cost to insulate an attic?” and unlock your business’s full potential.